He said, She said: Discrepancies in T and RH Readings

Anyone involved in managing the environmental conditions of a library, archive or museum has certainly encountered this dilemma: "These two monitoring devices are not showing me the same values. Which device is right!?" Discrepancies in temperature and relative humidity readings can lead to frustration, especially when the values represent a pivotal point where action may be necessary. These frustrations arise more often over measurements of relative humidity than temperature. In general, temperature is easier to measure and the sensors are more standardized. Humidity measurements are more complex, with myriad parameters that influence the sensors, the standards and methods for calibration, and the reliability of the readings. But, when discrepancies in readings occur, the right questions can help you to move beyond a "he said, she said" dispute. In fact, careful consideration of each device might prove that each reading was "correct;" or, further investigation could point to why one device might be reading out of range. If you find yourself in this situation, consider these few questions about your monitoring equipment:

- What is the nature of these two devices? What accuracy range, stability or most common sources of error can I expect from each device?

- What is the calibration history of these two devices? When was the last time each device was calibrated? What is the original calibration reference for the device? How reliable is that initial calibration reference?

- Do the displayed readings represent a point where I will need to take action? What are the implications of the different readings?

In the end, deciding which temperature or humidity reading is right is like deciding what time it is. If your watch tells you that it is 9:52 am, but the United States Naval Observatory reports the "official time" as 10:00am, what time is it? The answer, "It's about 10 o'clock" may be good enough. If it's not, then you must consider the rationale that you have to trust either source based on the nature of its technology, the quality and stability of its measurements and the reliability of its original reference point.

#1) What is the nature of this device?

When trying to decide which reading is "correct", it is important to consider the technology each device uses to measure temperature and relative humidity. The rationale that you have to trust each reading will be rooted in the monitoring technology of the device.

The first specification to look for is the stated accuracy of each device. It is possible for two devices to give different readings and still be within their stated accuracy range. Thus, each device can still be "correct" despite the discrepancy in their readings. If the stated accuracy for each device is ± 2%, then a difference of up to 4% RH is acceptable in the readings. For example, say two electronic data loggers sitting side-by-side on a shelf give two different %RH readings. The first reads 48% RH and the other reads 52% RH. Because the sensors will not necessarily read "off' in the same direction, one sensor could be reading 2% above the actual relative humidity, while the other sensor could be reading 2% below the actual relative humidity (hence the readings of 52% RH and 48% RH). Both readings are therefore within the specified accuracy range, despite the displayed difference of 4% RH.

As the accuracy range increases, so does the possibility of greater, yet acceptable, discrepancies in readings. For example, if the stated accuracy range of two devices is ± 5% RH, then a difference of up to 10% RH is possible. In this case, one device could read 40% RH and another could read 50% RH and each would still be reading within its identified specifications. Each device is still giving a "correct" reading, despite their apparent disagreement. This is why it is so important to know the accuracy range when questioning, and when acquiring, monitoring devices.

The nature of the technology also determines the stability of the device– in other words, how long the device will continue to read within its stated accuracy range– as well as the most common errors associated with the device.

To discuss these specifications, we will explore two of the most common types of monitoring technologies.

Wet-bulb/dry bulb thermometers –

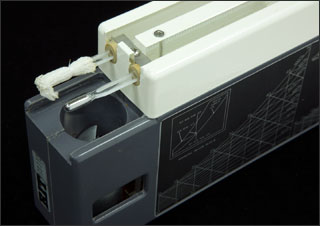

Sling psychrometers and Aspirated psychrometers

Wet-bulb / dry bulb thermometers, such as sling psychrometers and aspirated psychrometers, use two thermometers to measure temperature and relative humidity. One thermometer is dry and measures the air temperature; the other thermometer is wrapped in a wet-cotton wick. The humidity is read from a psychrometric chart based on the wet-bulb's cooler temperature caused by evaporation from the wet cotton wick.

Accuracy

According to ISO technical report 18931, the accuracy of wet-bulb / dry-bulb thermometers is, "under ideal conditions, seldom better than ± 5% RH."

Stability

Stability of the hardware is not the weakest link for wet-bulb / dry bulb devices. The thermometers that measure temperature have good long-term stability, so the problems with psychrometers usually arise from operator error or problems with the cotton wick. Stability is more important to investigate in electronic data loggers because the sensors have a tendency to drift over time.

Common Errors

Wet bulb / dry bulb devices have several common errors associated with measuring the relative humidity. It is common for the operator to read the wet bulb temperature before the cooling effect of evaporation has fully completed. Because this means a higher wet-bulb temperature, the final %RH calculation is inaccurately high. Other common errors stem from problems with the cotton wick, which is sensitive and needs to be replaced frequently. Inaccurate wet-bulb readings can be caused by swelling of the wick, which leads to poor contact with the thermometer bulb, or contamination of the wick from salt deposits and oil from the operator's fingers. For sling psychrometers, there is one other common place for error. Because no two people will "sling" a psychrometer in the same way, the readings can be inconsistent. The "repeatability" of these measurements is therefore poor and could be a cause for discrepancies between two devices.

Summary specifications of Wet-bulb/dry bulb thermometers |

|||

|

Accuracy |

Under ideal conditions, accuracy is seldom better than ± 5% RH. |

||

|

Stability |

Very good long-term stability of readings from thermometers |

||

|

Common Errors |

|

||

Electronic Data loggers

Modern data loggers use electronic sensors to measure both temperature and relative humidity. The most common electronic humidity sensors use technology based on electrical resistance or electrical capacitance. When the relative humidity of the environment changes, the sensor registers the change in its electrical resistance or its capacitance. By measuring this change, the sensor can calculate the relative humidity of the environment.

It is not necessary to understand the technical aspects of how these sensors work, but it is important to understand that not all electronic data loggers are created equally. The design specifications and calibration standards of electronic data loggers are diverse and can differ greatly.

Accuracy

There are currently hundreds of temperature and relative humidity data loggers available on the market. Of the most common electronic data loggers, the accuracy can be as refined as ±2% RH or as high as ±5% RH. The accuracy of an electronic data logger also depends on the reliability and accuracy of its calibration. (Read more about calibration in the following section…)

Stability

The stability of electronic sensors varies greatly. Under benign environmental conditions they can be very stable, but they can "drift" over time, causing their readings to fall outside of their original accuracy range. The tendency to drift can be more pronounced if the sensor is exposed to extreme levels of temperatures or humidity for prolonged periods of time. To ensure the most accurate readings, follow the recalibration schedule recommended by the manufacturer.

Hysteresis

One common problem with electronic humidity sensors is a behavior called hysteresis. Hysteresis is rooted in the physical nature of the sensors, and every sensor suffers from it to some extent. Hysteresis delays the sensor's response when the relative humidity comes up from a low humidity situation, or comes down from a high humidity situation. In other words, if the relative humidity was increasing, the sensor would give somewhat low RH readings; if the humidity was decreasing, the sensor would give somewhat high RH readings. Hysteresis behavior can not be eliminated entirely, but it can be checked for and mitigated in the calibration process. Not all data logger manufacturers check for the effect of hysteresis in their sensors, so inquire about the calibration process before purchasing a data logger.

Hysteresis behavior points to the complexity of making accurate humidity measurements and could play a part in discrepancies between humidity readings. Not all sensors will demonstrate the same hysteresis behavior, if any, and, consequently, not all sensors will read humidity in exactly the same way.

Inadequate Equilibration

Another common error in data logger readings is inadequate equilibration time of the monitoring device, especially when using a handheld unit or when moving a data logger from one location to another. However, unlike the hysteresis phenomenon, this error is not inherent to the sensor; it is solely an operator error! Even high performance sensors need time to settle down to adjust to new environmental conditions. The product guide for the Vaisala HMP46 humidity probe reports that it needs 15 seconds to reach 90% of the true RH value of an environment at 20oC; to reach 100% of its stated accuracy, it could take as long as 10 minutes. To ensure the most accurate reading possible, we generally recommend placing the unit in the space and leaving it unattended for about 30 minutes.

Summary specifications of Electronic Data loggers |

|||

|

Accuracy |

Unique to each data logger depending on sensors and operating range; common data loggers on market can be found with accuracy range from ±2% RH to ±5% RH. |

||

|

Stability |

Unique to each data logger, but electronic sensors tend to drift over time. It is best to follow the recommended recalibration schedule for each device. |

||

|

Common Errors |

|

||

Again, it is not necessary to understand the technical details of each monitoring device. However, it is important to be able to support your rationale to trust the readings you receive from any device. Information on how we handle these issues with our own data logger, the PEM2, can be found in the following article.

#2) What is the calibration history of this device?

Once you are aware of the technology and the specifications of your device, the next aspect to consider is its calibration history. The length of time since calibration, the method of calibration, and the reference or traceability of calibration will all impact the reliability of a device's readings.

Recalibration

If you question the readings of your device, recalibration is the best way to ensure that the device is still reading within its stated accuracy range. In general, the stability of the device determines how long it will be able to read correctly before recalibration is necessary. The thermometers used in wet bulb / dry bulb psychrometers tend to have good long-term stability, but readings can be compromised by operator errors and contamination of the cotton wick. (see above) The stability of electronic data loggers depends on the quality of the sensor because there is a possibility the sensor will "drift," and no longer read accurately. A typical recalibration schedule is every two to five years, but the stability of electronic sensors can be compromised if the device is exposed to extended periods of extreme temperature or humidity. For the best results, follow the recalibration recommendations of the manufacturer.

Method of Calibration

Another complexity in measuring relative humidity is the process of calibrating the humidity sensor. This applies to the recalibration method as well as the initial calibration that serves as the humidity reference of the device. Effective calibration is essential in determining the accuracy of a device, as noted in the Vaisala Calibration Book, which lists calibration in two of three main sources of "uncertainty" in a device:

- The uncertainty of the reference of the device. (In other words, the initial calibration of the device.)

- The uncertainty of the device itself – repeatability, linearity, hysteresis and short term stability.

- The uncertainty caused by the process used to calibrate the device.

Consider our analogy of asking for the time. Where do you look when you need to set your watch to the "correct" time? Do you look to your alarm clock (which was previously set 15 minutes early to compensate for the risk of oversleeping!) or do you look to an official source of time? If your initial reference for the time is inaccurate, your future readings will also be inaccurate.

Unfortunately, acquiring an accurate humidity reference is not as easy as checking the internet for an official source of time. Calibration of humidity sensors is complex and not all methods of calibration or calibration devices have the same reference source.

To ensure the quality of your device's calibration reference, look for the "traceability" of its calibration. The traceability chain of a calibration is like the lineage or pedigree of the calibration method. Vaisala defines "traceability" as the "property of the result of a measurement or the value of a standard whereby it can be related to stated references, usually national or international standards, through an unbroken chain of comparisons all having stated uncertainties."

The calibration history of the device is therefore an essential piece of information when questioning a discrepancy in humidity readings. Imagine, if one device is calibrated to one humidity reference, and a second device is calibrated to a different humidity reference, they could start with a different idea of what "40% RH" feels like. Add the uncertainty of the initial reference (first on Vaisala's uncertainty list) to the stated accuracy of each device (second on Vaisala's list, at least ±2% RH), plus the uncertainty of the calibration method (third on Vaisala's list, perhaps another ±2% RH), and you will see that the possibility for difference in the humidity readings adds up very quickly!

#3) Do the displayed readings represent a point where I will need to take action?

Finally, if confronted with two different temperature or humidity readings, the most important question may not be "which device is right!?" but, "what are the implications of these readings and do they represent a pivotal point where I need to take action?" To achieve the task of environmental management, it is essential to have a monitoring device that you trust. For that reason, you must be aware of the technology and specifications of your monitoring equipment, both when using it in the field and when looking to acquire more. We are unaccustomed to seeing differences in readings because we rarely monitor with two data loggers in an identical location. In normal use, our data loggers are distributed throughout our collections.

But, it is important to realize that in reality, even under ideal conditions, with high performance monitoring equipment, two devices will rarely agree to the exact same value.

Bibliography

International Organization for Standards. Imaging materials – Recommendations for humidity measurement and control. ISO/TR 18931:2001 (E), 2001. www.iso.org

Vaisala, Calibration Book. Document 213538, April 2006. www.vaisala.com